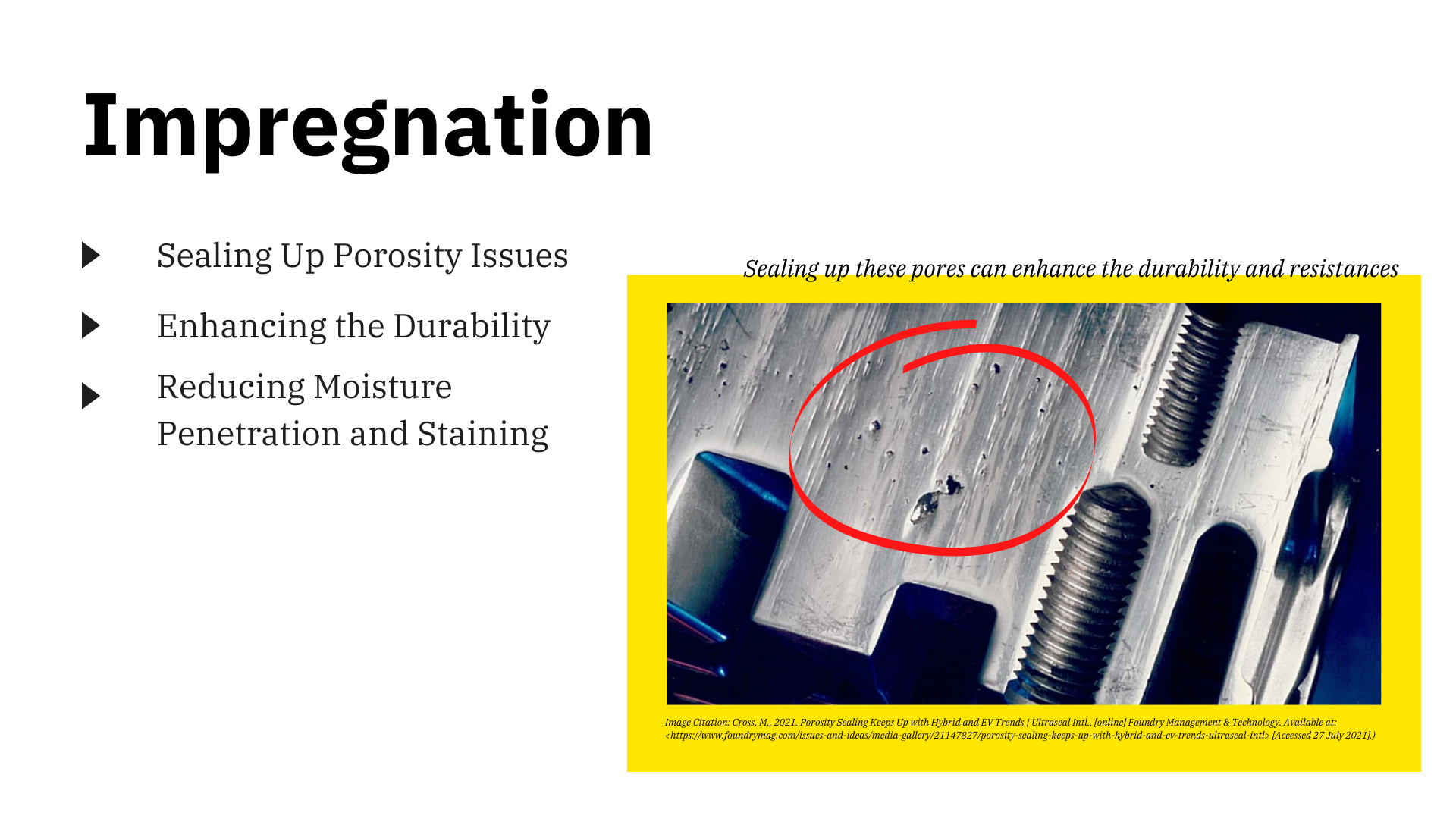

- Impregnation

- Pre-assembly coasting

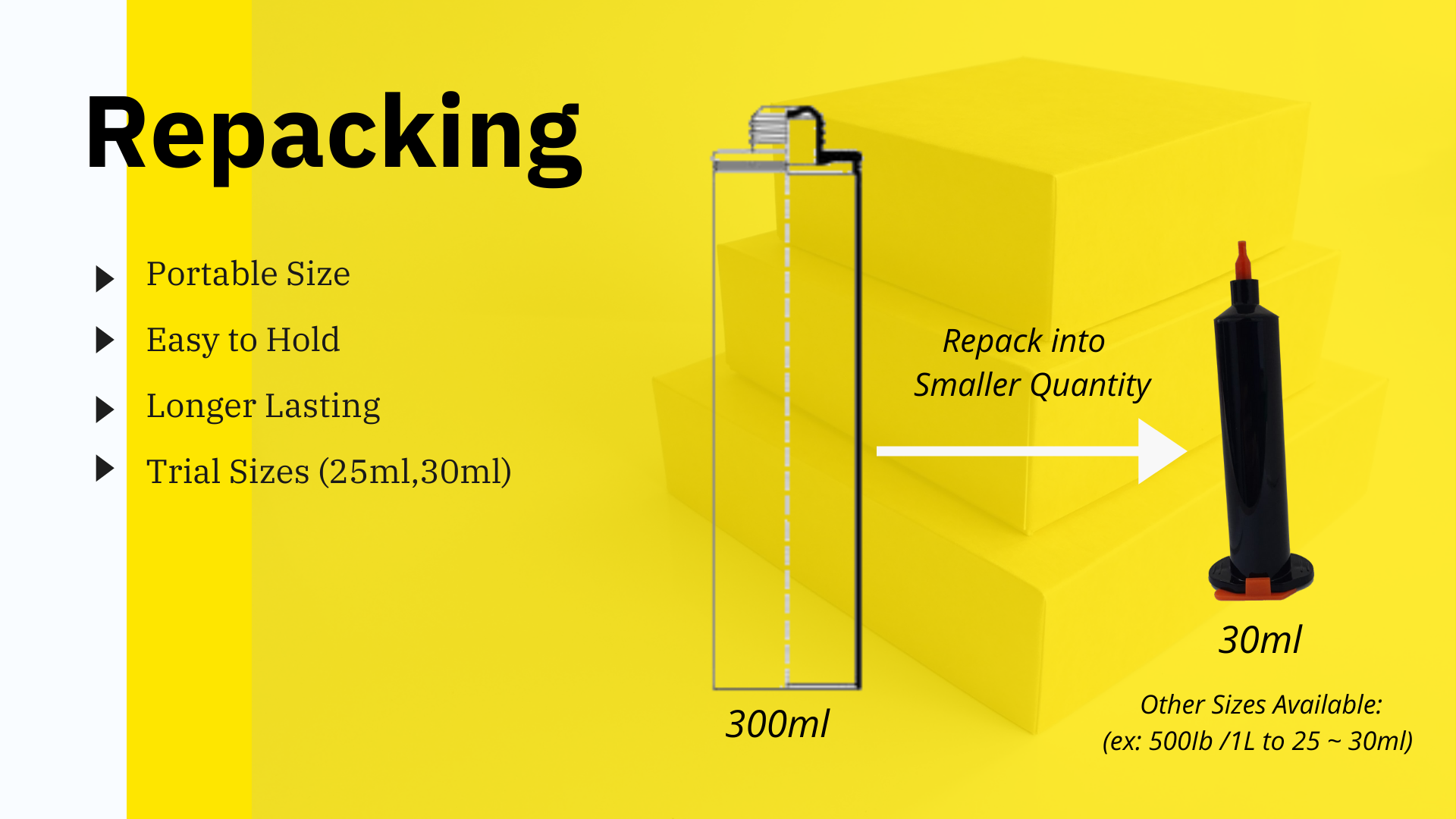

- Repacking

- Low Pressure Molding (encapsulation)

For Porosity sealing of metal parts

Impregnation is also known as Porosity Sealing for metal parts. This process effectively seals the parts of the material. Providing the most reliable approach to solving porosity issues.

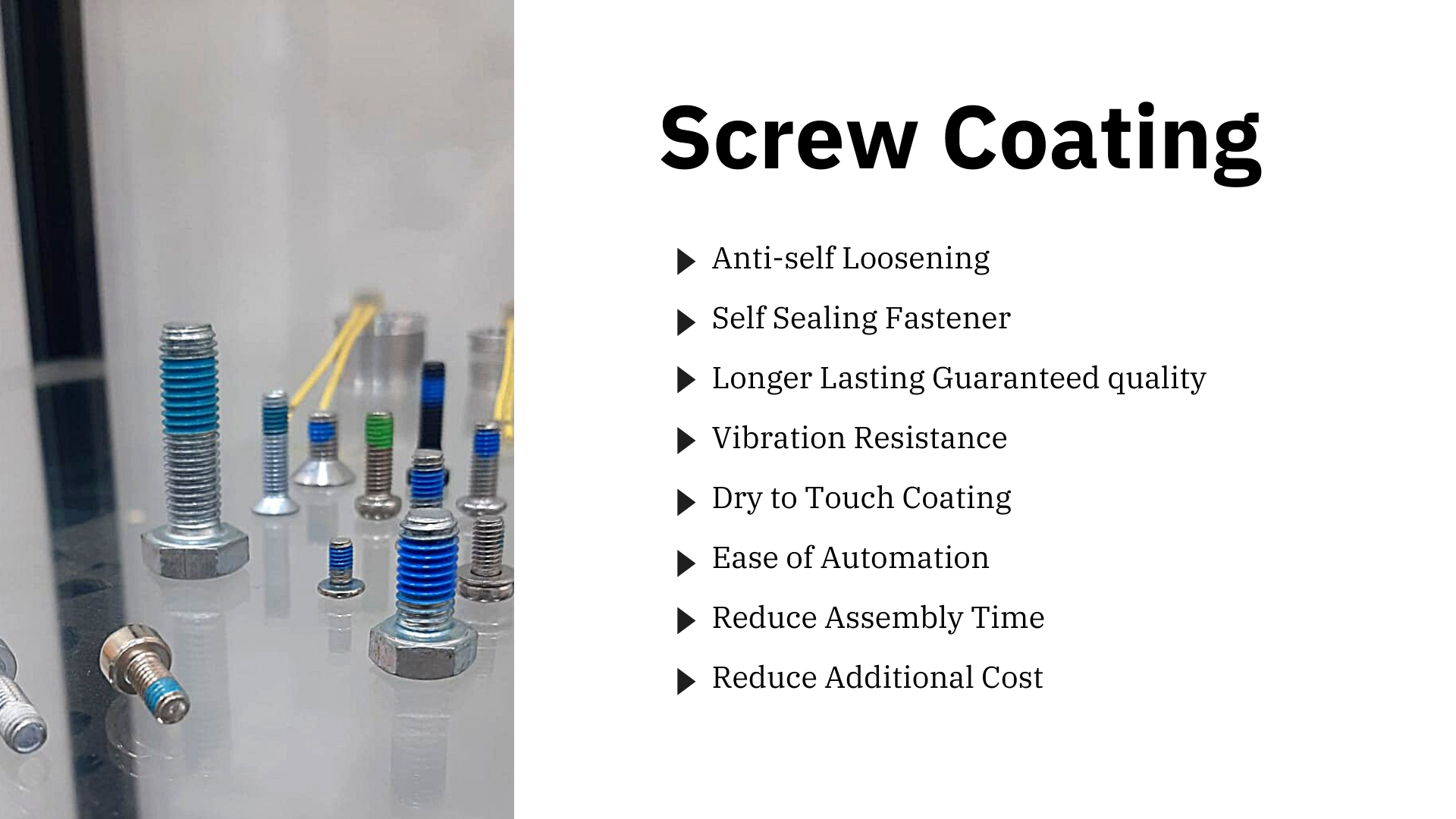

Pre-applied screw for anti self loosening

The “Pre-applied” is a coating applied to threaded screws, bolts and pipe fittings which help to sustain Threaded Parts.

The additional layer of coating helps the screws to be more durable and

prevents loosen issues

Your portable choice

Repackaging helps to have a steadier grip and easier application which allows the applicant to produce consistent results

For superior sealing and protection of the critical parts on the PCB

A low pressure molding process by hotmelt adhesive to achieve superior sealing and protection of electronics concompent.

This superior technology offers higher productivity compared to those that are widely used in current sealing processes such as the 2-component casting/potting resins or silicones.

The low pressure molding process is not only environmentally-friendly, it also contributes to the total cost reduction through significant improvement in productivity.

Low Pressure Molding (process)

- Mold design

- Machine series: vertical injection / horizontal injection